Upstream Oil & Gas, Skid-Mounted Modular Process Systems Engineered to Suit Your Needs

IFS is a process engineering firm that builds a wide range of modular, well site production systems for the Upstream Oil & Gas Industry. All of our products are skid-mounted and ready to “plug-in.” Our engineers will build-to-suit according to your exact specifications and can install your completed skid units for oil and gas anywhere in the world.

Below are some examples of the well site equipment we can engineer for you.

Upstream Oil & Gas Modular Packages

Fuel Gas Conditioning Package

Fuel Gas Conditioning Package

(FGCS – 100.0)

Designed to remove solids, liquids, and aerosols from natural gas. Aspen Plus Process Simulation is used to insure the gas is heated to 50 degrees F above the dew point.

Fuel Gas Conditioning Membrane Package

Fuel Gas Conditioning Membrane Package

(FGCS-300.0)

Designed for Natural Gas Liquid, H2O, H2S (for “Gas Sweetening”) & CO2 removal from a Natural Gas Stream.

Heat Transfer / Hot Oil Package

Heat Transfer / Hot Oil Package

(HTHO-100.0)

Designed to store/heat/circulate Heat Transfer Fluids which are used for indirect heating of combustible liquids and gases.

Production Sand Removal Package

Production Sand Removal Package

(PSRS – 100.0)

Designed to remove sand deposited in oil and gas equipment (production separators, inlet separators, crude oil dehydrators, etc.) without interrupting operation.

Produced Water Injection Package

Produced Water Injection Package

(PSED – 100.0)

Designed to dispose of produced water separated from Oil & Gas production by pressurizing the produced water for injection in a disposal well

Oil Pipeline Pump Package

Oil Pipeline Pump Package

(PSMP-100.0)

Designed to pressurize/transfer low viscosity crude oil from storage or a LACT unit to an export pipeline.

Heavy Oil Pipeline Packages

Heavy Oil Pipeline Packages

(PSHP-200.0)

Designed to pressurize/transfer high viscosity crude oil from storage or a LACT unit to an export pipeline.

Wet/Dry Oil Pump Package

Wet/Dry Oil Pump Package

(PSLP-100.0)

Designed to transfer wet or dry oil from a storage tank to a LACT unit or pipeline pump package.

Water Injection Pump Package

Water Injection Pump Package

(PBPS – 100.0)

Designed to dispose of produced water separated from Oil & Gas production by pressurizing the produced water for injection in a disposal well

Chemical/Methanol Injection Pump Package

Chemical/Methanol Injection Pump Package

(CCIS – 100.0)

Designed to safely store/meter/inject chemicals into an Oil & Gas production stream or produced water for control of separation, foaming, scale, corrosion, etc. Individual metering pump heads are used for each injection point.

IRCD Package

IRCD Package

(SCIS-100.0)

Designed to safely store/meter/inject chemicals into an Oil & Gas production stream or produced water for control of separation, foaming, scale, corrosion, etc. Injection Rate Control Devices are used for each injection point.

Black Powder Filtration System

Black Powder Filtration System

(BPFS – 100.0)

Designed to remove Iron Sulphide, Iron Oxides and other contaminates from gas transmission lines

Nitrogen Generation System Packages

Nitrogen Generation System Packages

(N2GS-100.0)

Designed to deliver continuous supply of 95% – 99.95% pure nitrogen gas. Solutions for high ambient temperatures, fixed dew point control for buffer gas, coil tubing for well servicing and export line commissioning.

Open/Closed Drain Sump Package

Open/Closed Drain Sump Package

(PSSS – 100.0)

Designed to collect flammable/toxic liquids (closed drains) or non-flammable liquids (open drains) from runoff in a single or double wall sump with leak detection. Automatic level controls start/stop pumps which transfer the waste for further handling.

IntegraHeat™ Electric Process Heating Package

IntegraHeat™ Electric Process Heating Package

(IEPH – 100.0)

Designed to electrically heat hydrocarbons (natural gas for dew point control or crude oil for viscosity reduction). Accurate temperature control…

Electric Process Heater Control Panel

Electric Process Heater Control Panel

(CP6012 – 100.0)

Offers convenient, economical control of resistive loads. Completely eliminates the engineering, design, component procurement, assembly and testing steps required to build a control panel.

Automation & Controls

Automation & Controls

(PACS – 100.0)

Monitors and controls IFS packaged equipment. The controls can be skid-mounted and prewired or remote mounted in an unclassified area.

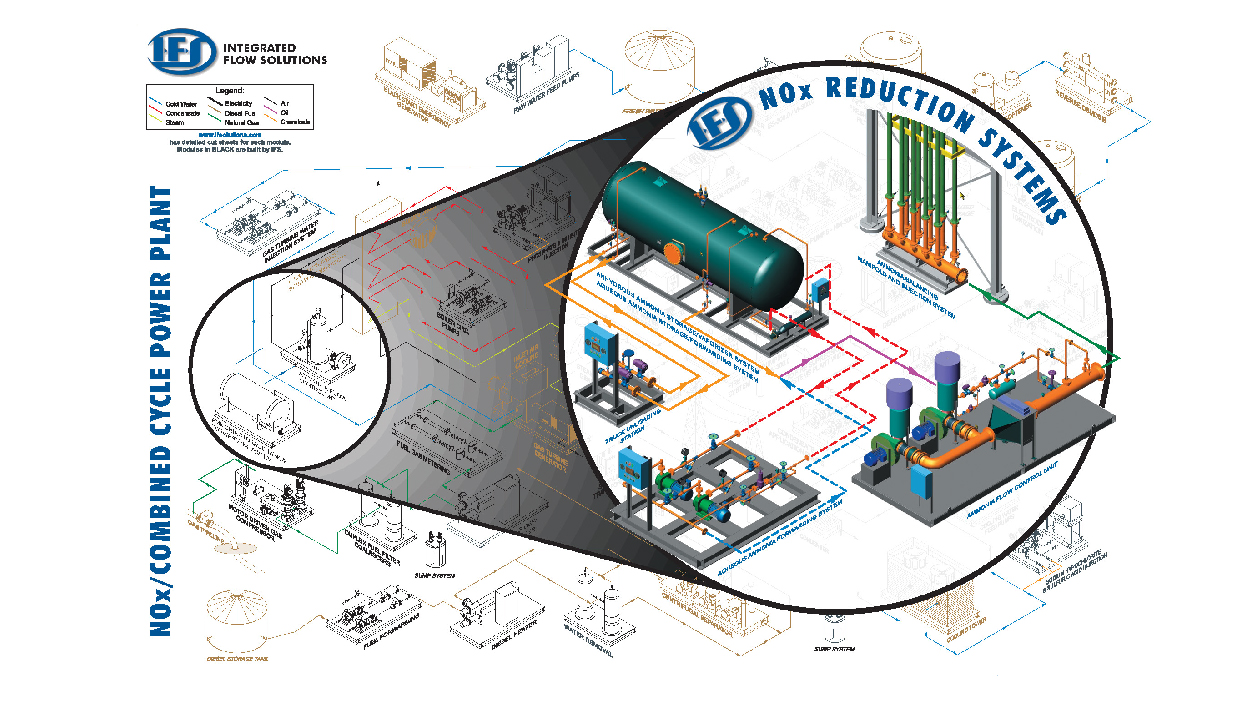

FPSO Equipment Packages (PDF)

FPSO Equipment Packages (PDF)

This site map of an FPSO unit highlights some of the Process, Mechanical and Utility Packages that IFS offers customers needing “engineered-to-fit” packages that arrive ready to “plug into” the vessel systems. Process packages include heater, gas conditioning, nitrogen generating and fuel oil conditioning units.