Midstream Oil and Gas

Ultimate Guide to LACT Units: Functionality, Benefits, & Innovations

June 25, 2024 Welcome

What are LACT units, and why are they important? For starters, they help to minimize errors and disputes when it comes to measuring and allocating oil and gas — a key piece of infrastructure that keeps the industry running smoothly.

What is a LACT Unit?

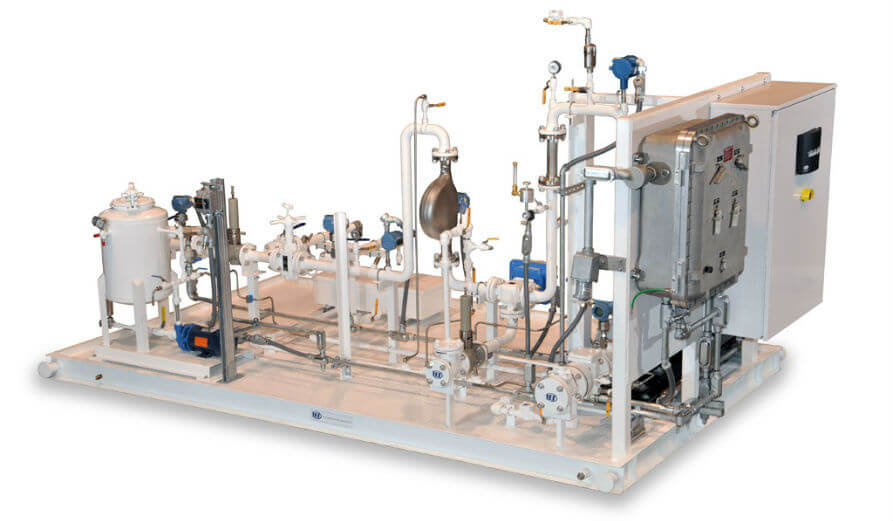

A Lease Automatic Custody Transfer (LACT) unit is a system used to measure and transfer ownership of crude oil or other petroleum products from a production site to a pipeline or storage facility. The primary purpose of a LACT unit for oil and gas is to ensure accurate measurement, sampling, and recording of the transferred product, facilitating fair and transparent transactions between parties.

Functionality of LACT Units

To fully appreciate the value of LACT units, we must first understand how they function to ensure precise measurement, accurate sampling, and efficient custody transfer of petroleum products. So, how do they work?

1. Measurement

LACT units use flow meters, typically Coriolis, positive displacement or turbine meters, to measure the volume of oil passing through the system. These meters are calibrated to ensure accuracy and are often equipped with temperature and pressure sensors to account for variations that could affect measurements.

2. Sampling

A representative sample of the oil is taken during the transfer process. This sample is used for quality analysis, ensuring that the oil meets the specified standards and contractual requirements. Automated sampling systems ensure consistent and accurate sampling.

3. Base Sediment and Water (BS&W)

LACT units include so called BS&W monitors. Once a BS&W monitor detects off-spec product, the LACT unit activates a divert valve that send the product back to the source to prevent sending crude oil with high concentrations of water or solids down the pipeline.

4. Control and Automation

Modern LACT units are equipped with advanced flow computers that automate the measurement, sampling, and reporting processes. Flow computers include programmable logic controllers (PLCs) and human-machine interfaces (HMIs) for easy operation and monitoring.

5. Data Management

LACT units are integrated with data management systems that record and store measurement data, sample results, and operational parameters. This data is used for reporting, regulatory compliance, and resolving any disputes that may arise.

Benefits of LACT Units

These automated units offer a range of benefits, including precise measurement of oil and water flow rates, reduced operating costs, and improved data accuracy.

- Accuracy: LACT units provide precise measurements of oil volumes, ensuring that transactions are based on accurate data. This accuracy is essential for fair financial settlements between buyers and sellers.

- Efficiency: Automated LACT skids streamline the oil and gas custody transfer process, reducing manual intervention and minimizing the risk of human error. This leads to faster and more efficient operations.

- Compliance: By ensuring accurate measurement and documentation, LACT units help operators comply with industry regulations and standards, such as those set by the American Petroleum Institute (API).

- Quality Control: Automated sampling and quality analysis ensure that the transferred oil meets the required specifications, maintaining product integrity and value.

- Reliability: Modern LACT systems are designed for durability and reliable performance, even in harsh field conditions. This reliability translates to less downtime and lower maintenance costs.

At IFS/DXP, we offer state-of-the-art LACT units designed to meet the highest standards of performance and reliability. Contact us today to learn more!

Innovations in LACT Units

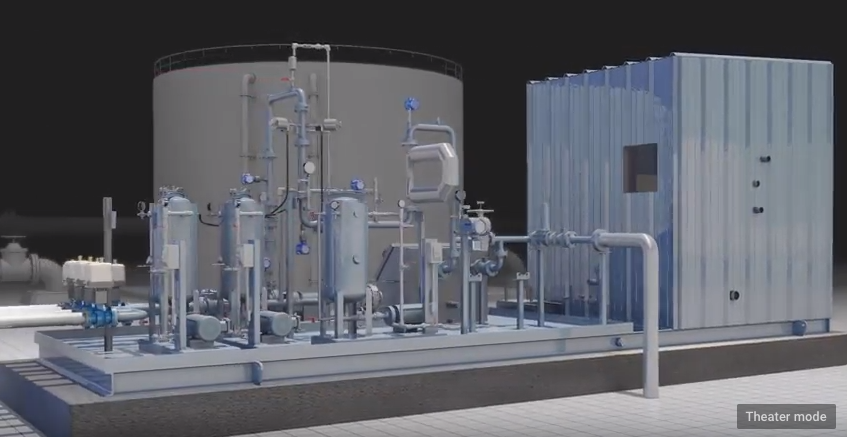

As technology advances, LACT units have seen significant innovations that enhance their performance, accuracy, and efficiency, ensuring they meet the evolving demands of the oil and gas industry.

- Advanced Flow Measurement Technologies: Innovations in flow meter technology, such as the use of Coriolis flow meters and ultrasonic meters, have enhanced the accuracy and reliability of LACT units. These meters offer improved precision and are less affected by variations in temperature and pressure.

- Enhanced Automation and Control: The integration of advanced automation systems and smart sensors has made LACT units more efficient and user-friendly. Real-time monitoring, remote control, and automated reporting capabilities are now standard features.

- Improved Sampling Systems: Innovations in sampling technology ensure more accurate and representative samples. Automated custody transfer systems can adjust sampling frequency and volume based on flow conditions, enhancing the overall accuracy of quality analysis.

- Data Integration and Analytics: Modern LACT units are equipped with data management systems that integrate with cloud-based platforms and analytics tools. This integration allows operators to analyze data in real time, optimize operations, and make informed decisions.

- Environmental Considerations: Innovations in LACT unit design also focus on reducing environmental impact. Enhanced separation techniques minimize the release of gas and water into the environment, and improved sealing and containment systems prevent leaks and spills.

Discover LACT Units Provided by IFS/DXP

Say goodbye to manual errors and hello to streamlined operations with our advanced technology. Our LACT skids provide real-time data monitoring and analytics, ensuring precise measurement and compliance with industry standards. Experience seamless integration and enhanced productivity with our top-of-the-line LACT units. Invest in reliability, invest in accuracy — choose our LACT units for your oil measurement needs today!

For more information on our LACT units and how they can enhance your oil and gas operations, contact IFS/DXP today. Let us help you achieve optimal performance and reliability in your custody transfer processes.