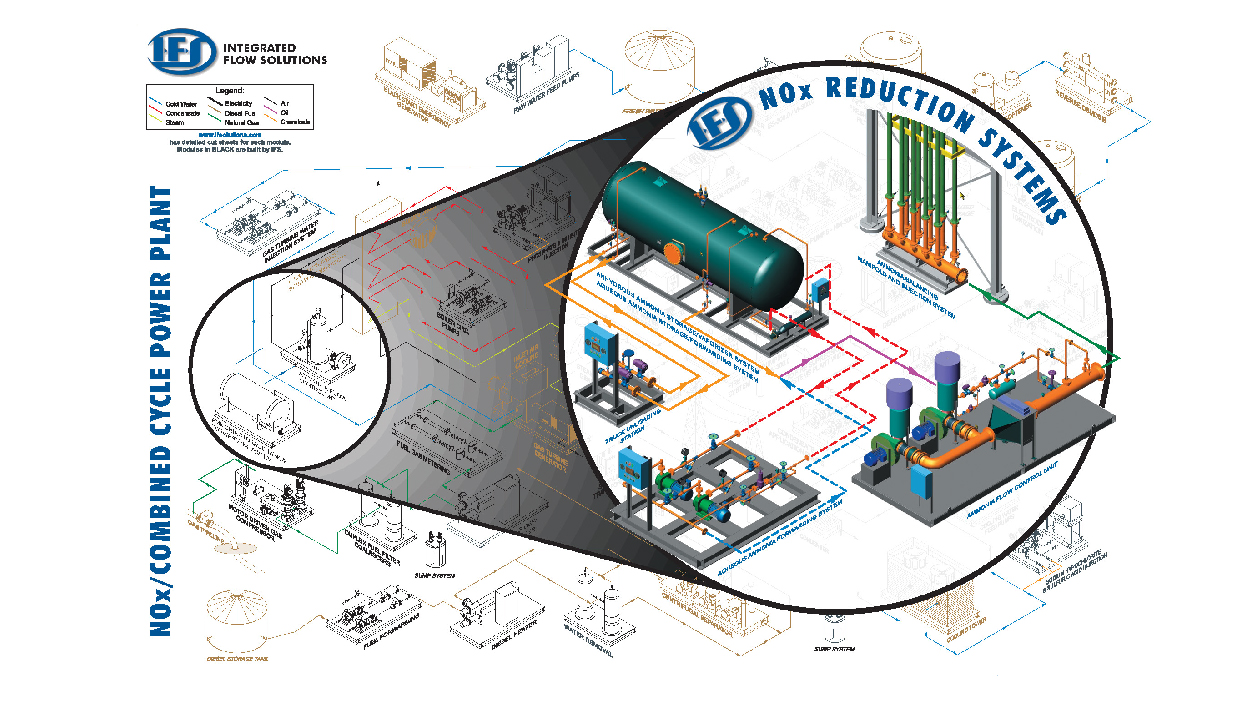

SCR Ammonia Unloading, Storage, Distribution & Vaporization System

Modular, Engineered-to-Order, Shipped Ready to Plug In

Integrated Flow Solutions Ammonia Unloading, Storage, Distribution & Vaporization System is designed to provide ammonia (anhydrous or aqueous) reactant to a Selective Catalytic Reduction (SCR) unit for removal of NOx from flue gas. Ammonia is delivered by truck or railcar and unloaded into storage tanks. The ammonia is forwarded to the Ammonia Flow Control Unit (AFCU) which generates ammonia gas for injection into the flue gas upstream of the SCR. IFS provides the complete system.

Integrated Flow Solutions Ammonia Unloading, Storage, Distribution & Vaporization System is designed to provide ammonia (anhydrous or aqueous) reactant to a Selective Catalytic Reduction (SCR) unit for removal of NOx from flue gas. Ammonia is delivered by truck or railcar and unloaded into storage tanks. The ammonia is forwarded to the Ammonia Flow Control Unit (AFCU) which generates ammonia gas for injection into the flue gas upstream of the SCR. IFS provides the complete system.

Benefits

|

|

Industry Standards:

|

|

Standard Features:

- IntegraSafe Unloading Station

- Local indication of:

- Tank level

- Tank pressure

- Flow indication

- Local manual/automated valve operation

- Local indication of:

Standard Features (cont.):

|

|

Optional Features:

- Class 1, Div 2 Hazardous Locations

- Compliance with Plant/Engineering Specifications

Additional Services:

- “Aspen Plus” Process Simulation Software used to guarantee process conditions

- Installation / Training / Start – Up Supervision

- Extended warranty

- Nationwide Service Network