Fuel Gas Conditioning

AECOM Fuel Gas Separator

May 8, 2018 Welcome

Jon Alexander - IFS ASME Welder

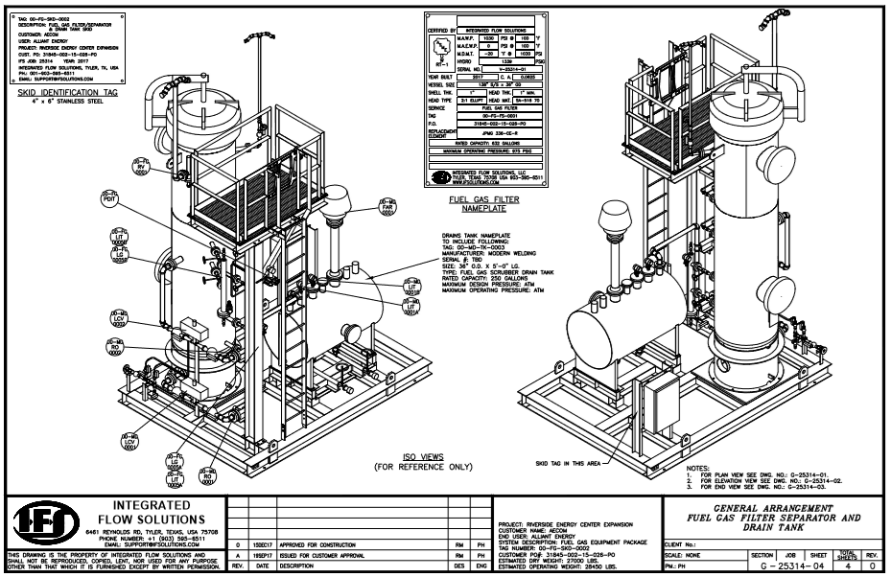

AECOM Fuel Gas Separator Skid

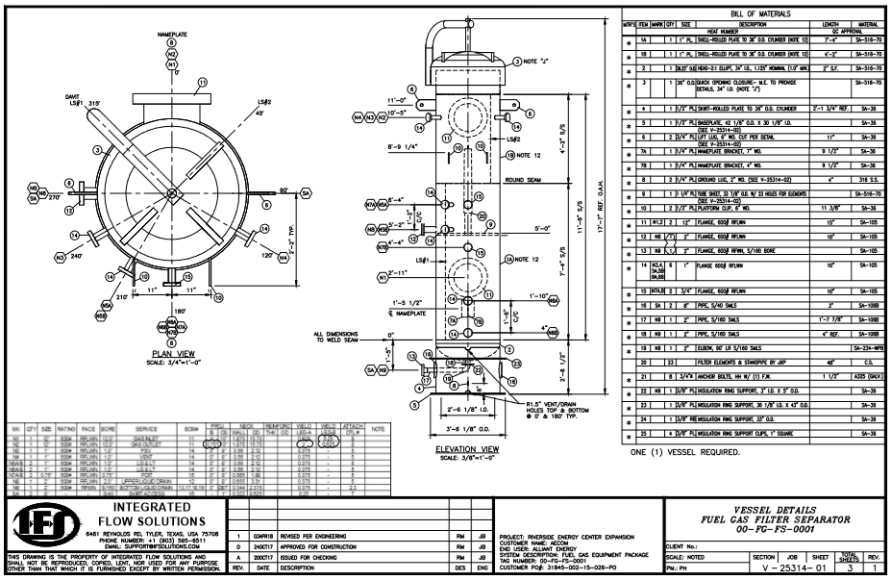

AECOM Fuel Gas Separator Vessel

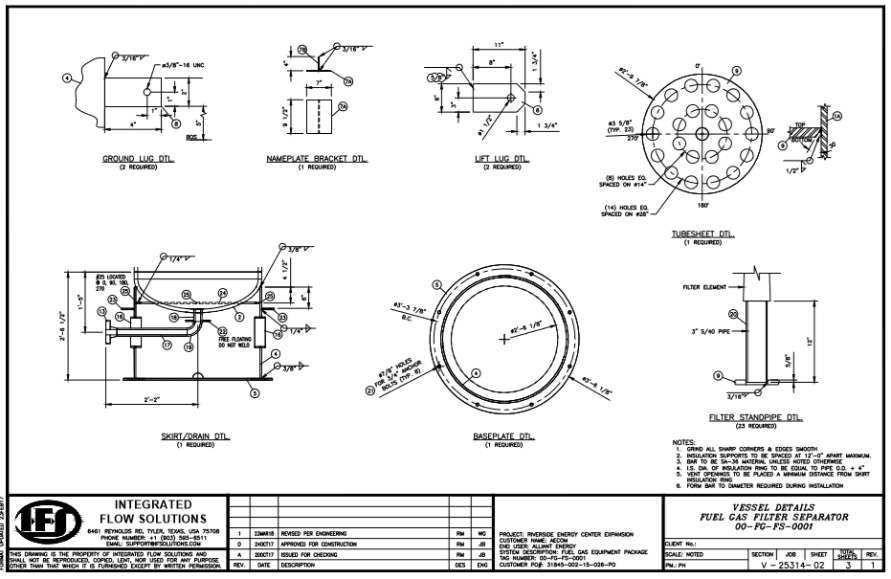

AECOM Separator Detail

IFS recently completed the fabrication of the Fuel Gas Separator, part of the complete Fuel Gas Treatment Train contracted by AECOM Energy & Construction, Inc. for the Alliant Riverside Energy Center Expansion Project in Beloit Wisconsin. Jon Alexander, one of IFS’s best ASME code welders fabricated the Fuel Gas Separator (photo 1).

The IFS Supplied Fuel Gas Train includes the following equipment:

- Fuel Gas Dew Point Heater Skid

- Fuel Gas Filter / Separator Skid

- Fuel Gas Drain Tank Skid

- Gas Chromatograph

- High Pressure Reduction Station

- Start Up High Pressure Reduction Station

- Auxiliary Boiler Low Pressure Reduction Station

- Building Heater Low Pressure Reduction Station

- Slam Shut Valve

- Combustion Turbine Emergency Stop Valve

- Combustion Turbine Emergency Stop Valve

- Aux Boiler Emergency Stop valve

- Building Heater Emergency Stop Valve

- Fuel Gas Compressor Reduction Station

IFS will complete the shipment of these packages in May 2018.