Uncategorized

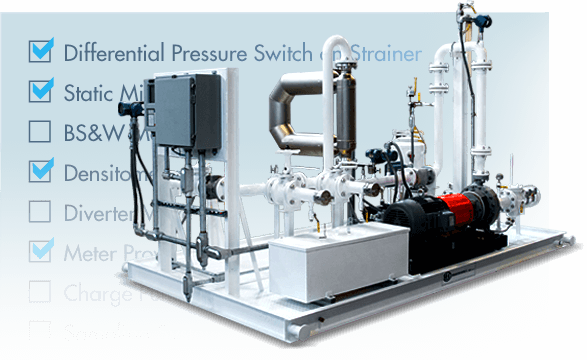

Optional Features to Improve Your LACT Unit Operations

September 29, 2024 Welcome

LACT units are versatile systems that can be tailored to meet the unique needs of your operation. With customizable options, you can ensure that your LACT unit performs precisely as required for your specific applications

Below, we’ve listed 12 of the most beneficial features available for LACT units to help you customize a system that meets your operational needs.

1. Automatic Sampling Systems

Automatic sampling systems allow for the continuous collection of fluid samples during the transfer process. This feature ensures that product quality can be assessed in real time, aiding compliance with industry standards and regulations.

2. Water Cut Monitors

Water content in oil affects both the quality and value of the product, making water cut monitors essential in maintaining oil purity during custody transfer. These monitors detect the amount of water present in the crude oil, providing critical data for accurate billing and regulatory compliance. By including a water cut monitor, operators can minimize penalties due to excess water content and ensure that the transferred product meets customer specifications.

3. Density Measurement Devices

Real-time density meters help with accurate volume calculations by adjusting for oil density changes. This feature reduces losses due to miscalculations and improves billing accuracy.

4. Advanced Flow Control Valves

Flow control valves regulate the flow rate through the LACT unit, providing more control over the transfer process. By investing in advanced, automated flow control valves, you can achieve greater precision in flow rate management. This feature is especially valuable for operators looking to increase transfer efficiency and reduce wear on LACT unit components, leading to lower maintenance costs over time.

5. Digital Flow Computers

Integrating a digital flow computer with your LACT unit adds a layer of automation, capturing and storing data on flow rate, volume, density, and other parameters in real time. Digital flow computers streamline data reporting, making it easier to monitor performance, analyze trends, and maintain accurate records for regulatory compliance. With digital data tracking, operators can optimize their LACT unit’s efficiency and generate detailed reports with minimal manual intervention.

6. Remote Monitoring Capabilities

Remote monitoring has become an essential feature for efficient operations. Remote monitoring allows operators to access LACT unit data and control features from anywhere, improving oversight and enabling quick adjustments if issues arise. This capability is especially useful for remote or high-risk locations where regular manual checks are challenging or costly.

7. Temperature Compensation Features

Temperature fluctuations can significantly affect crude oil density and, in turn, measurement accuracy. Adding temperature compensation devices to your LACT unit allows you to adjust readings in real time for temperature changes, ensuring that the volume of oil transferred is calculated accurately. This feature helps to prevent revenue losses associated with temperature-induced discrepancies and improves measurement precision.

8. Prover Loops for Verification

Prover loops are optional systems that verify and recalibrate flow meters in the LACT unit. This feature is ideal for operations where precise measurement is critical, as it ensures flow meters remain accurate and reliable over time. Regular calibration through prover loops can minimize the risk of inaccurate measurements, saving costs related to product loss or disputes in custody transfer.

9. Automated Data Logging and Data Printer

Automated data logging records key operational metrics like flow rate and temperature, which is useful for audits and compliance. Data printers allow real-time printing of operational data, ensuring accurate documentation.

10. Enhanced Filtration Systems

Filtering out impurities from the oil during transfer can protect LACT skid components and improve the quality of the transferred oil. Enhanced filtration systems remove contaminants such as sand, silt, or water from crude oil, reducing the risk of equipment wear and potential blockages. This feature ensures a smoother transfer process, extending the life of both the LACT unit and downstream equipment.

11. Automated Pump Controls

Pumps are integral to maintaining consistent flow through the LACT unit. Automated pump controls manage pump speed and efficiency, adapting to real-time conditions and ensuring a consistent transfer rate. This feature reduces manual intervention, prevents wear and tear on pump components, and helps operators maintain stable flow rates across varying operational conditions.

12. Customizable Alarms and Notifications

Customizable alarms alert operators to issues such as temperature spikes or flow irregularities, providing added safety and reducing the risk of costly interruptions. Emergency Stop Devices (ESD) can also be included for quick shutdown in critical situations, enhancing personnel and equipment safety.

Customize Your LACT Unit Operations with IFS/DXP

IFS/DXP specializes in customizable LACT units and can help you integrate the right options for your application. From real-time data logging to advanced flow control, we offer a wide range of features to support your operation’s unique requirements.

Ready to upgrade your LACT unit? Contact IFS/DXP today.